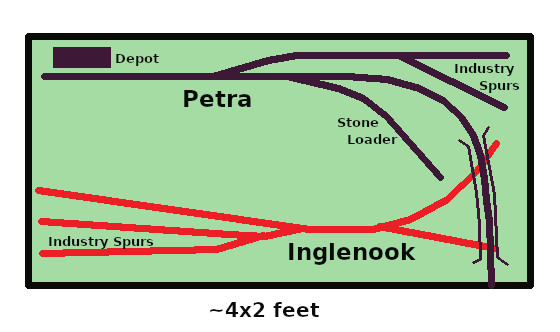

A 2-in-1 4×2 feet layout, with 2 micro track plans.

This 2-in-1 layout was designed to be effectively 2 micro layouts sharing the same area, and designed to replace the Petra Pizza layout. The Petra Pizza layout was representative of a fictional shortline branch that left the CSX mainline south / south west of Cumberland, MD, in the United States and traversed a mountainous region where there was an aggregate quarry which the shortline served. As this layout was partially a replacement for the Petra Pizza layout, the scenery would have to be at least somewhat similar to that layout, which meant mountainous scenery. The initial plan was to have an Inglenook switching area on a lower level at the front, and the upper level to an expanded Petra branch terminus on a top level. It was made to fit in a bookshelf underneath the Brazilian micro.

The bottom level Inglenook is representative of a fictional switching area, which I decided to call “The Nook”, in the area not far from, and south-south-west of, Cumberland, MD between Cumberland and Petra Junction (where the Petra branch starts). The minimum track radius of the Inglenook trackage is 18″, and short Peco Y turnouts are used. This would allow all my motive power to be used on it as they can all negotiate 18″ radius curves with ease. The lead track to the right of the turnout that leads to the spurs allows for 2 x 40 scale feet cars and a short 4 axle switcher. The Inglenook trackage is a 3-2-2 Inglenook track arrangement, meaning that of the 3 spurs on the left of the plan one holds 3 cars and a locomotive, and the other two hold 2 cars each. The track to the right of the 3 spur ladder allows for 2 cars and a 4 axle switcher up to an EMD GP length and 2 cars 50 foot cars.

The upper level Petra trackage uses a number of short left or right hand Peco setrack turnouts, and has a minimum radius of 15″. This means most (if not all) of my motive power should be able to be used on it and allows for more compact approach trackage. This level uses my short Plymouth ML-8 and NSWGR X class 2 axle switchers on it while also allowing the occasional appearance of one of my 4 axle Alco S2 switchers on the Petra trackage.

Layout Construction and Scenery

The layout has a 42 x 19mm dressed pine sub-frame, topped with 12mm plywood, which was then topped with a layer of 30mm thick XPS foam (similar to extruded foam) to make the lower level. This allowed for some below track level scenery such as a creek, river or valley. Then 50mm XPS foam was used to build up the upper trackage level and mountainous scenery.

After the scenery was formed scatter, foliage, trees and other scenery items were added. The mountain areas and upper level are covered with trees and other items from the Petra Pizza layout and odds and ends I had stored from previous layouts. Once the scenery was completed to a point where it could be moved into our living space, it was moved out of the shed where it was being built and installed in a bookshelf that had the Brazilian Micro on top.

Track

This layout has Peco set track and turnouts on the Petra level, and a mixture of set track, Peco turnouts and flexitrack on The Nook level. Turnouts are all Peco Insulfrog, allowing for the operation of multiple DC only locos if the layout was to be operated using a DC controller (which it initially was during testing).

Operation

To operate the Inglenook trackage on the lower level, a train comprised of a switcher and up to 3 cars is staged by hand on the spur indicated on the top left of the Inglenook trackage. It is then a process of moving cars around so that outbound cars are in the track at the top left and any cars inbound are in the 2 left hand spurs underneath it. There are certain rules or conventions that are sometimes associated with the operation of an Inglenook layout (such as 3 cars in / 3 cars out, using a random cars selection generation method, and only allowing uncoupling inside the spurs rather than elsewhere), most of which I ignore! In other words, I operate it however I want to.

To operate the Petra trackage on the upper level, a 2 or 4 axle switcher and a few cars (usually 2 or 3) is staged on the bridge in the bottom right hand corner. This is then moved into the depot and relevant spurs according to what type of train it is, and any outbound cars made up into a train. Because the Petra trackage has no runaround, the idea is that there is already a switcher in the spurs that can release the arriving switcher from it’s train and assist in building the outbound train.

Like most of my previous layouts constructed over the last few years, this layout is designed to be operated using Virtual Interchanging, ie, waybills indicating cars and freight are used to select which cars to use and move freight to and from locations ‘beyond the layout’.

Electrics

The layout is operated using a Roco Lokmaus 2 DCC system, which I have had for a number of years now, which allows for multiple controllers and operators. Most of the motive power on the Petra trackage doesn’t have a DCC decoder. This means the Petra trackage needed to have an isolating track section so one locomotive can move around while another is either electrically isolated by a turnout or isolated in the isolated track section. The isolating section was added next to the Petra depot, which allows an incoming train to have it’s motive power isolated while another loco from a spur electrically controlled by the position of the Peco insulfrog turnout’s point blades then moves the cars on the train so \it’s mpotive power can ‘escape’. So that only the DCC system is needed to operated the layout the Petra trackage is actually controlled via a DCC decoder wired in between it and the DCC system.

Blog posts for this layout can be found under the 2-micros-in-1-layout category.